Complete solution for decor and ceramic mosaic plant

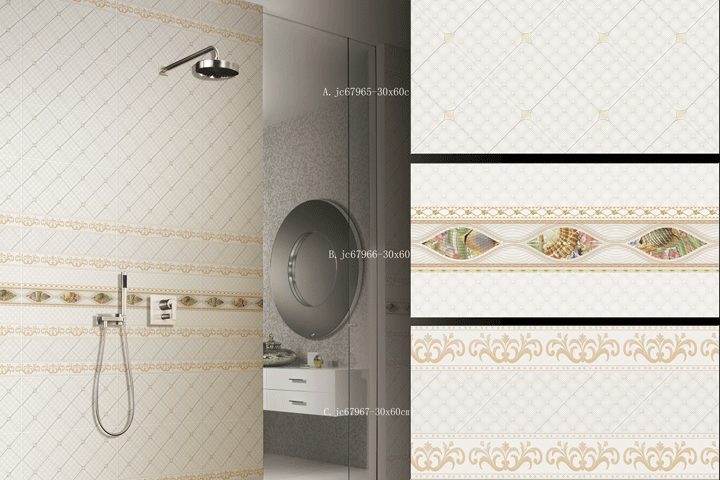

There are two types of decor & border used for wall

in ceramic tile industry: cutting (A) and pressing (B).

A. The way of cutting finished tile and making decor & border as follows:

(1)Traditional method: Cut final product into the size according

to requirements, then print color by screen on decal paper, then remove decal paper

from water and paste it on the surface of cut tile, then print granular and then fire in the kiln.

If need gold, silver or luster decoration, repeat the above printing processes and fire again in lower temperature.

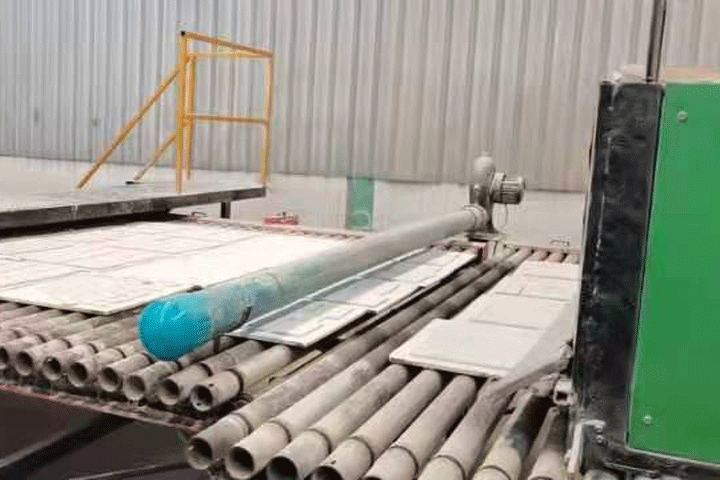

The main machines: cutting machine, small kiln, glaze line with some

functional machine.

(2)Inkjet method: the color pattern is sprayed on the whole tile

by inkjet machine directly, then print granular and fire in kiln with higher

temperature. If need more decoration like gold or luster, then print it on tile,

then fire in low temperature again.

The main machine: small kiln, inkjet machine, glaze line with

some functional machine.

B. The pressing method for making decor & border as follows:

The main difference between the pressing method and the above

cutting method is that the powder is directly pressed into border

with the required size, including plain and concave convex,

including but not limited to rectangle / square and other shapes,

and then glazed and fired, followed by various surface decoration,

such as inkjet color printing gold paste / platinum, etc.

The resin border can also be made by pressing method and

used for matching ceramic tile products too.

The main machines:

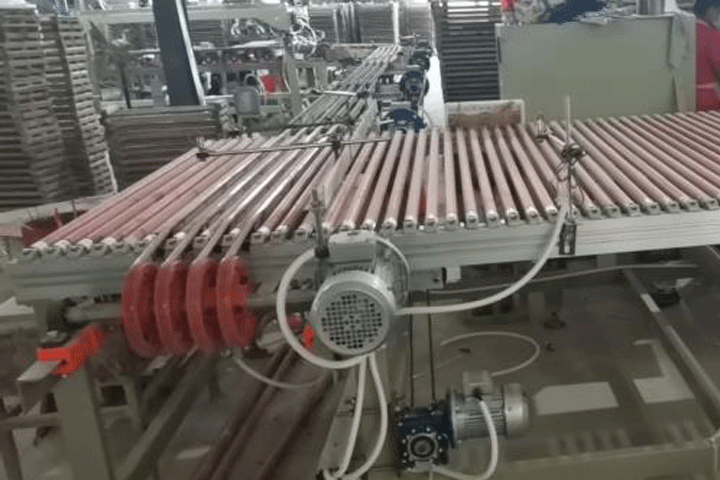

Small press, connection roller table, glaze line with functional machines.

关闭

关闭